Structural Health Monitoring

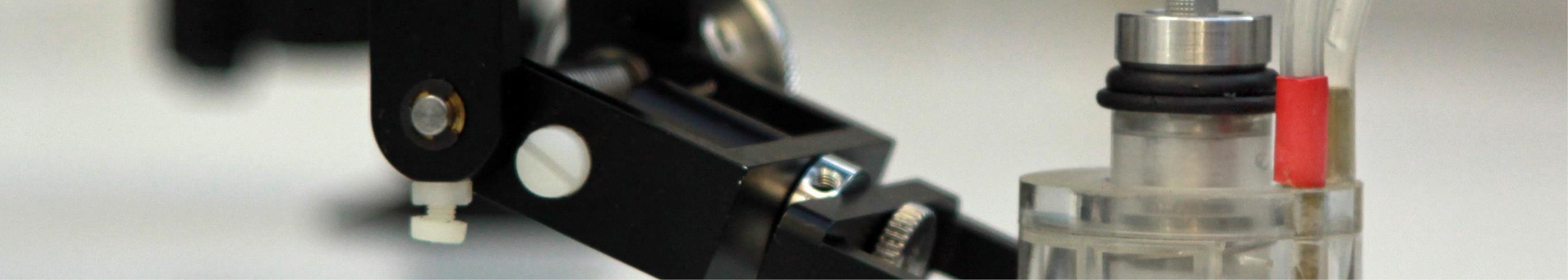

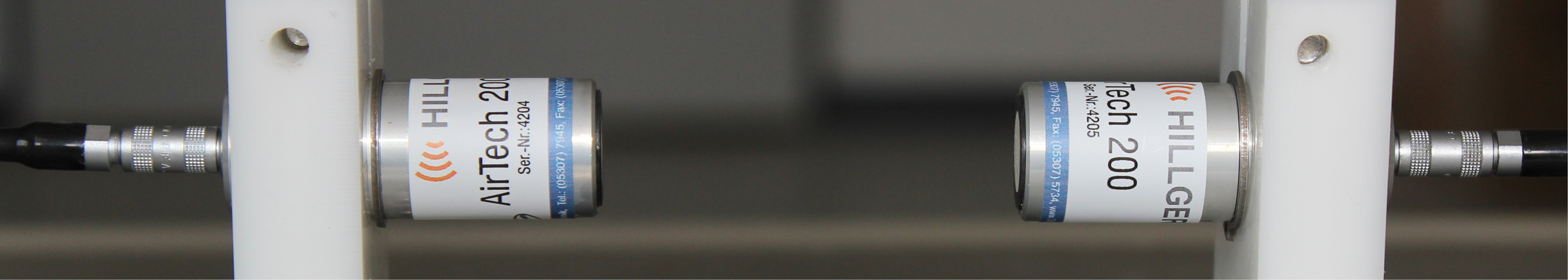

Structural Health Monitoring (SHM) with guided waves (e.g. Lamb waves) is a method for structure-integrated condition monitoring. The waves are typically excited and received by a network of piezoelectric transducers firmly applied to a plate-shaped specimen (see Figure 1).

Depending on the frequency, different modes occur, which in the general case propagate dispersively, anisotropically and inhomogeneously in the specimen. They interact with all structural discontinuities through reflection, refraction, diffraction and mode conversion. From the selective information (A-scan) of the sensor network, conclusions can be drawn about the condition of the component by means of suitable signal processing.

Fig. 1: CFRP plate with stringers and applied SHM transducer network.

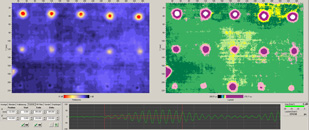

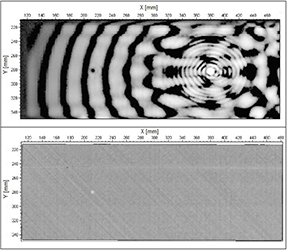

Figure 2 compares the results of a guided wave investigation and a water-coupled pulse-echo investigation of a CFRP plate. The upper image shows the wave field at 200 kHz, about 44 μs after excitation. The lower image shows the C-scan of the defect echo of a water-coupled investigation with 10 MHz. The 6 mm flat bottom hole at x = 210 mm and y = 280 mm is clearly visible with both methods.

Fig. 2: Comparison of guided waves (top) and the C-scan of a water-coupled investigation with 10 MHz (bottom) of a CFRP plate.

This technique allows cost- and time-efficient inspections of safety-relevant components. Since the sensor network remains permanently on the component, it does not have to be demounted for an investigation. Depending on the operating conditions, components can even be investigated online during operation.