Facilities for Tube Inspection

For rotationally symmetrical components, we have developed various systems in which a rotating axis is combined with a linear axis. The component is tested in a spiral form. The results are output by our ultrasonic software Hillgus in the proven 2D view.

RobockScan

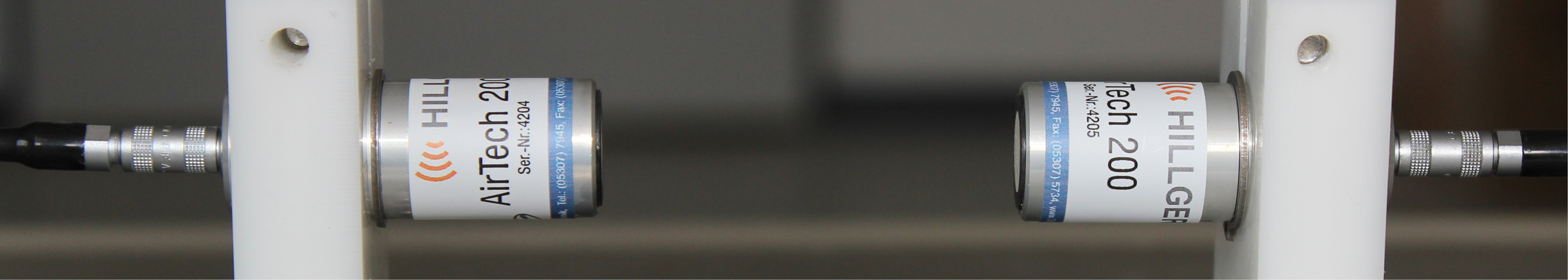

The RobockScan system was developed for inspections of rotationally symmetrical composite components in through-transmission technique. This system has two mechanically or electronically coupled linear axes, one of which is moved into the component. The component is rotated on roller brackets. All axes are step motor driven. The max. length of the specimen is up to 7 m at one-sided access. The diameter range is between 200 and 1600 mm. The mass of the specimen may be max. 300 kg.

ConeScan

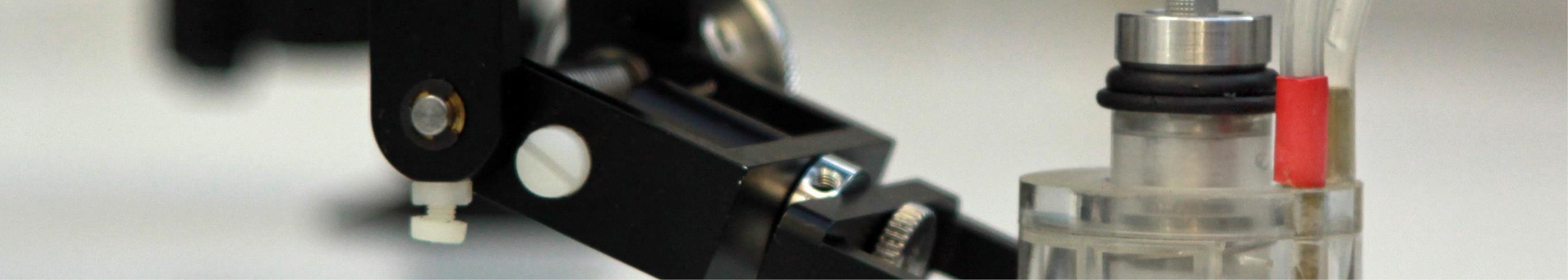

The ConeScan system was developed for investigations of conical components. A linear axis is guided to the component from the outside. The second axis is used for rotation of the component. The investigation is carried out as a spiral scan with squirter or water gap coupling. Excess water is collected by a ring tank, filtered and reused. The system is shown in Figure 1. The shown cone has a height of 1.1 meters. The mass of the specimen may be max. 50 kg.