Facilities with Immersion Tank

For investigations in an immersion tank, our ImmersionScan mechanics are available in different sizes. These scanning mechanics can be supplemented by an optional water management system, which offers a software-controlled water supply, drainage as well as storage and filter functions.

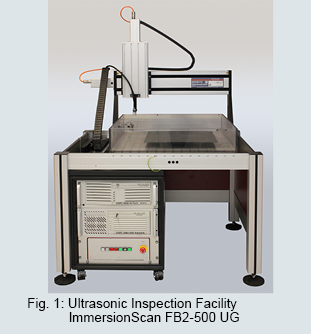

ImmersionScan FB2-500 UG

- Immersion Technique for flat components

- Scanning area: 500 x 500 mm

- Digital controlled water management system (optionally)

- Prepared for Phased Array Technique (optionally)

- Driven by step motors or servo motors

- Max. movement speed of snanning axis: 400 mm/s

- Max. resolution of scanning and index axis: 0,05 mm

- Repeat accuracy 0,02 mm

ImmersionScan FB3-1000 UG

- Immersion Technique for flat components

- Scanning area: 1200 x 1000 mm

- Digital controlled water management system (optionally)

- Prepared for Phased Array Technique (optionally)

- Driven by step motors or servo motors

- Max. movement speed of snanning axis: 400 mm/s

- Max. resolution of scanning and index axis: 0,05 mm

- Repeat accuracy 0,02 mm

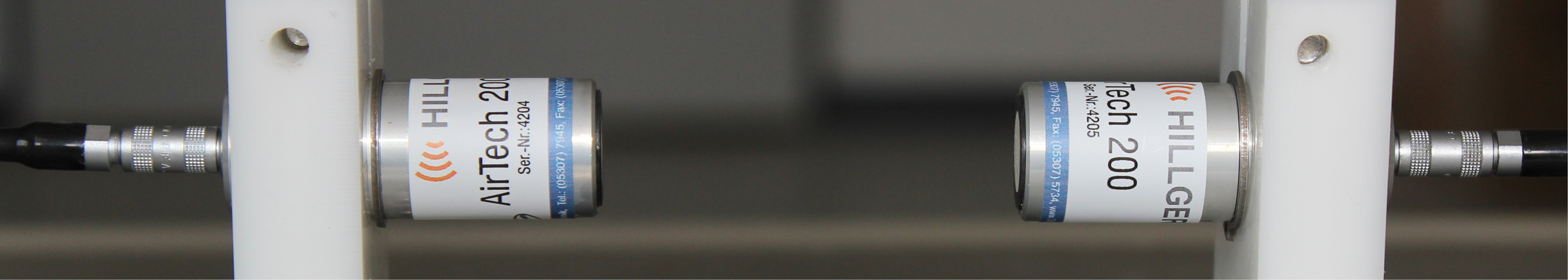

Water Management Systems

We offer a modern and easy-to-use water management system for all of our water-coupled inspection systems. With Standard and Professional, two different expansion stages are available. In addition, a spray nozzle connection and a LIUS connection are optionally available for both stages.

Water Management System Standard

With our Water Management System Standard, the water of the inspection tank can be pumped through a filter in order to get cleanded. The built-in pumps and valves are controlled via buttons on the inspection system or via the Hillgus software interface. In addition, the drain function enables the inspection tank to be emptied into a connected drain. The inspection tank is filled with fresh water by a manual supply.

Summary of functions:

- Digital control

- Filter function

- Drainage function

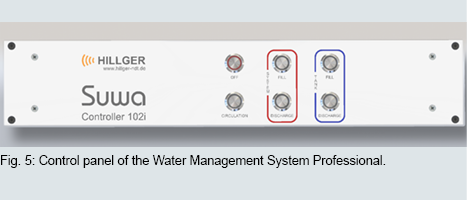

Water Management System Professional

With our water management system Professional, all functions of the standard version are included. In addition, a water reservoir tank is installed here, in which the supplied water can rest in order to minimize air bubbles. Furthermore, a filling function is integrated with which fresh water can be fed directly from a water connection into the reservoir tank or inspection tank. Even with the professional version, all functions are accessible via buttons on the inspection system or via the Hillgus software interface.

Summary of functions:

- Digital control

- Filter function

- Drainage function

- Filling function

- Reservoir tank

Additional Options

Option spray nozzle connection

The water management system is provided with an additional connection to which a water hose with a spray nozzle is connected. The hand-held spray nozzle can be used to flush away air bubbles under the ultrasonic probe or a test specimen inserted in the inspection tank

Option LIUS connection

The water management system is provided with additional connections to which our LIUS adapter for a local water coupling is connected. With the help of the adapter, components can be investigated which cannot be submerged under water or which are too large for the inspection tank. The adapter and the ultrasonic probe can be guided by hand or with the aid of a cardanic mounting on the scanning mechanics. With the LIUS adapter, probes with a frequency of up to 65 MHz can be used.

Option Squirter connection

The water management system is equipped with an additional connection to which a squirter nozzle can be connected. The nozzle can be used to investigate components which are too large for the immersion tank or which do not allow the LIUS adapter to be guided along their geometry