Manual Inspection

Manual hand-guided inspections are usually performed in direct contact with a coupling paste. This requires A-scan ultrasonic inspection devices which, similar to an oscilloscope, display the received signal as amplitude over time.

With USBUS, we offer a range of powerful and cost-effective A-scan ultrasonic inspection devices for research, development and training. The USBUS devices can be connected to any Windows PC or laptop via a USB interface. Our high-quality and proven ultrasound cards and an ADC are integrated. The devices are controlled with our proven Hillgus software. With the Bt-scan option, Hillgus also delivers results as a live cross-sectional image of the specimen. This occurs during the manual movement of the probe or component.

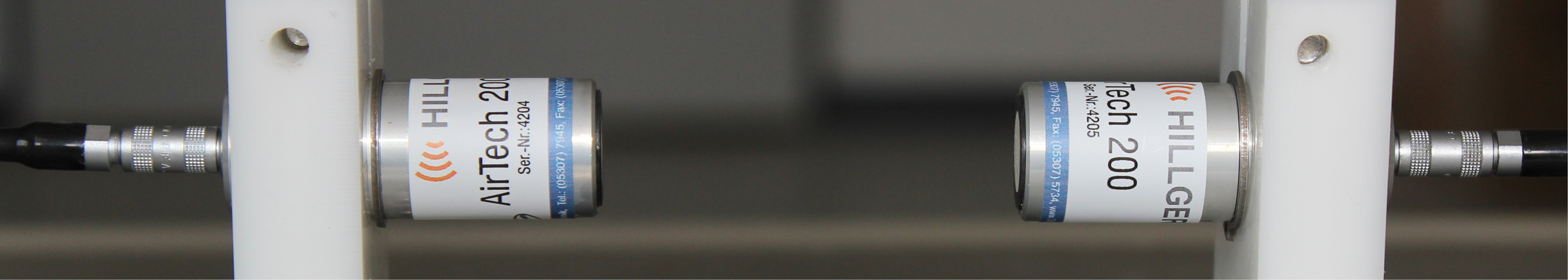

System family USBUS

USBUS refers to a new device family with a very good price/performance ratio. Here, the user uses an existing PC (or laptop). The connection to the USBUS system is made via a USB interface. The following USBUS systems are available for different inspection tasks.

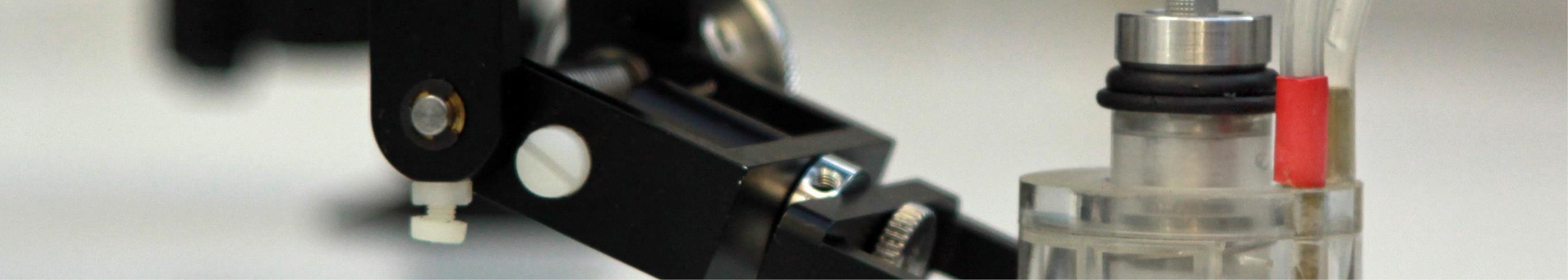

Fig. 1: Manual material testing

Frequency range | Applications | Flyer | |

|---|---|---|---|

| USBUS 3010 | 0,1 bis 20 | Composites and metals | USBUS |

| USBUS 3010 Hf | 0,15 bis 35 | Defects in composites even with a high resolution in thinner components | USBUS |

| USBUS 3010 VHF | 0,1 bis 65 | Bond inspections, inspections of composite components, thickness measurement up to 0.1 mm steel, probe characterization | USBUS |

| USBUS 3060 UHF | 1 bis 200 | Semiconductors, contacts, bonding, thickness mesasurement up to 0.1 mm steel, probe characterization | USBUS 3060 UHF |

| USBUS 3011 NF | 0,01 bis 10,5 | Concrete, wood, steel, composites, foams | USBUS |

Tab. 1: Applications for the USBUS-Family

Portable Computer

On request, all devices can also be installed in a portable PC or in an industrial PC. It is then possible to extend the device to an imaging system.

Download